Non-contact temperature monitoring is an essential means to ensure the safety and reliability of equipment. Portable and stationary infrared thermometers play an important role in preventative maintenance applications as an alternative to portable thermal

Non-contact temperature monitoring is an essential means to ensure the safety and reliability of equipment. Portable and stationary infrared thermometers play an important role in preventative maintenance applications as an alternative to portable thermal imaging cameras (e.g., the latter are often used in OEM schemes and large factories that require a large number of temperature measurement points for infrared monitoring).

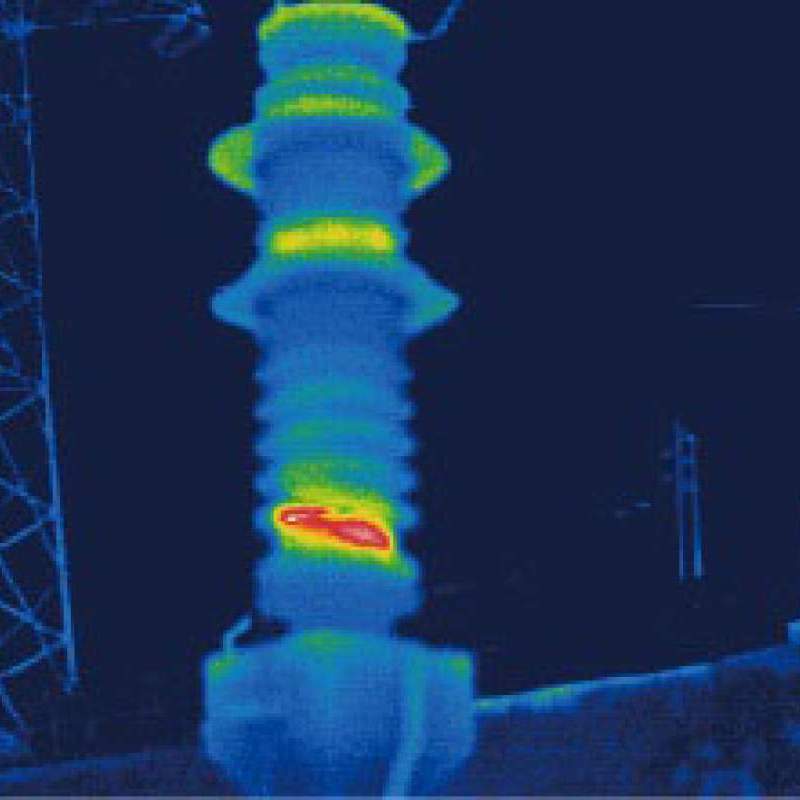

With the naked eye alone, it is almost impossible to detect defects in switchgear, fuses, motors or electrical connections. At the same time, it is well established that almost any electrical installation will exceed its normal operating temperature in the event of an anomaly. Portable infrared thermometers are increasingly being used to detect such weaknesses as a complement to portable thermal imaging cameras. Stationary pyrometers are primarily used in factories where electrical or mechanical components that need to be monitored are often difficult or impossible to reach humans.

Once you've identified critical components with your camera, a handheld infrared thermometer can be used to further facilitate quick and easy verification. Not only that, but it also allows you to achieve fast inspections between -32ºC and 900ºC. The integrated laser sight (with criss-cross) enables accurate aiming of the object to be measured, which in turn indicates the correct size of the measuring area. At the push of a button, the temperature value can be read out on the display with an accuracy of 0.1ºC. When the temperature exceeds or falls below a pre-programmed threshold (max/min function), an alarm signal is output, prompting you to perform a system scan of the measured object and quickly find the source of the fault.

One of the main issues that needs to be considered in all measurements is whether the optics of the infrared thermometer are able to realistically and appropriately capture hot spots. The optical resolution of infrared thermometers, which are currently sold at low prices on the market, is not ideal, and the point lasers on these devices can only be used for aiming, not for the size of the measurement area. As a result, the temperature measurement readings for superheated objects are often lower than their true temperature when measuring temperatures with the help of these devices. If, for example, a small electrical component is overloaded (e.g., and there is a rapid rise), if the measurement area is too large, this phenomenon will only increase in temperature slightly; As a result, potentially dangerous situations cannot be detected.

The thermometer's new dual-lens optics enable the determination of even the smallest objects. After switching to Close-Focus Mode, you can accurately determine even targets up to 1 mm in size. The aiming of the thermometer is achieved with the help of two laser beams intersecting at a near focal point (distance: 62 mm). Until now, the devices on the market have been either used for long-distance measurements or are designed for the measurement of small volumes. To do this, consumers have to purchase multiple thermometer models or interchangeable optics. In contrast, our product is an all-rounder thermometer – you can easily switch between close focus by simply flipping its selector.

© 1997-2019 ruidaneng 京ICP备13005932号-2 Terms of use | Privacy policy

中文版

中文版 English

English